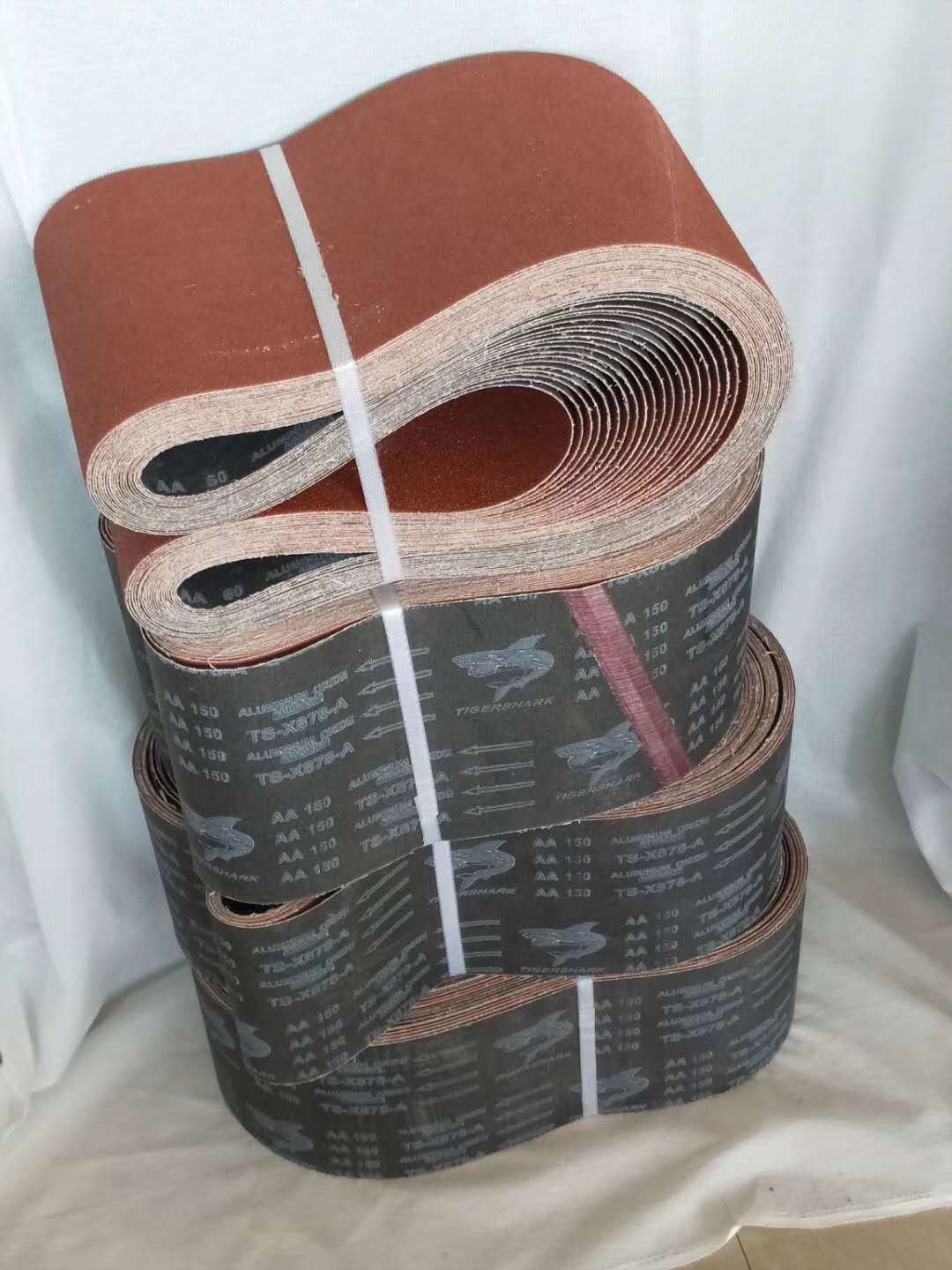

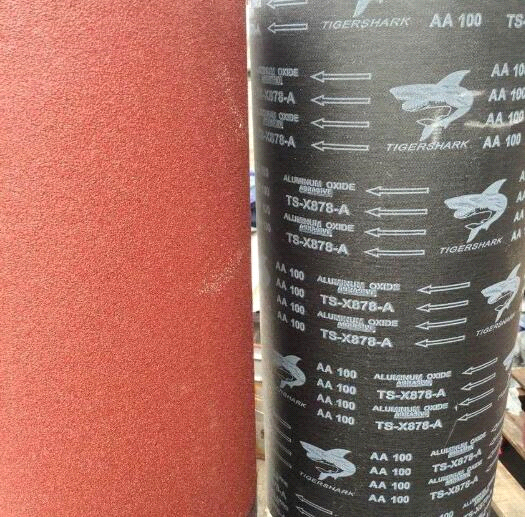

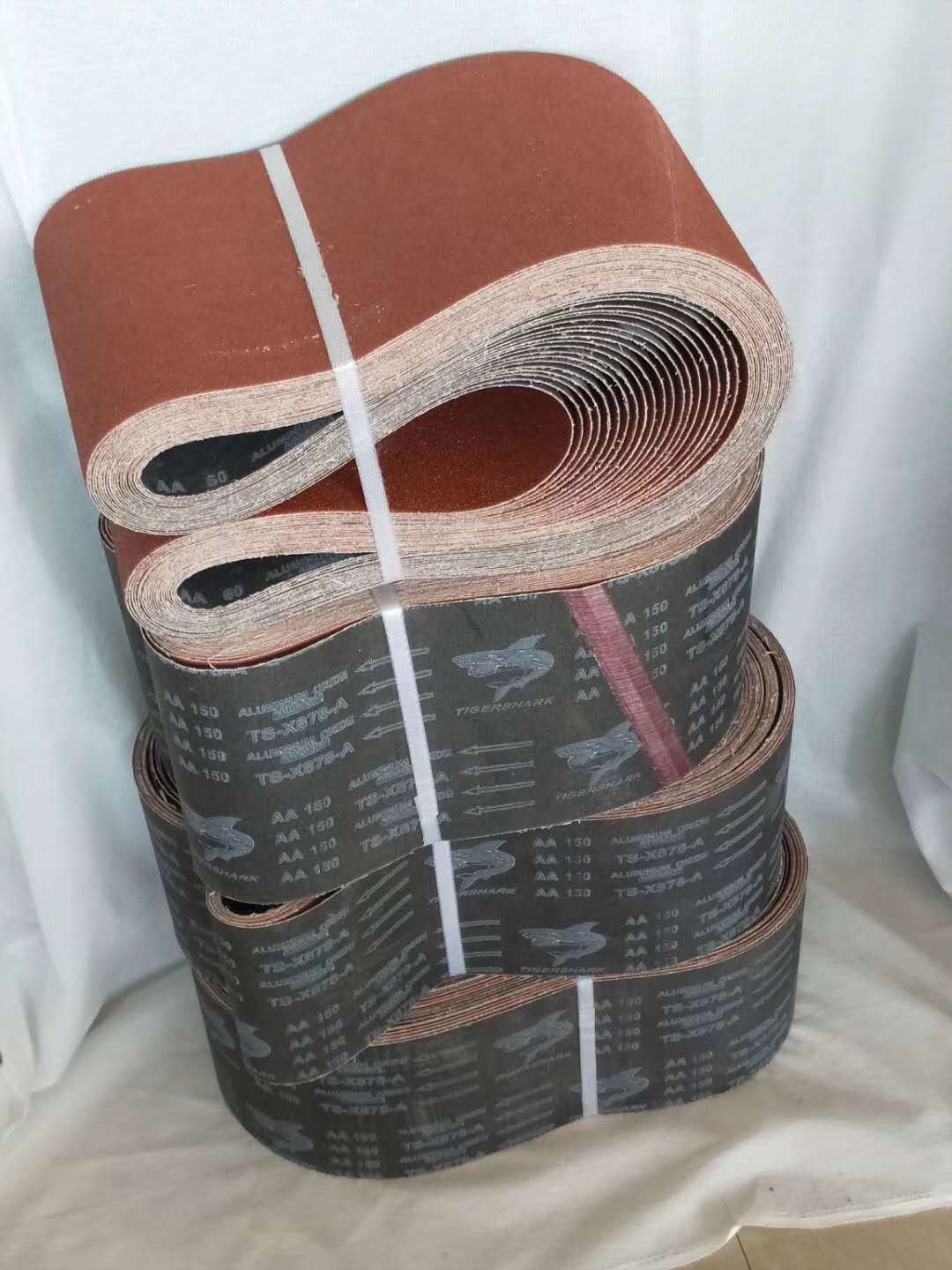

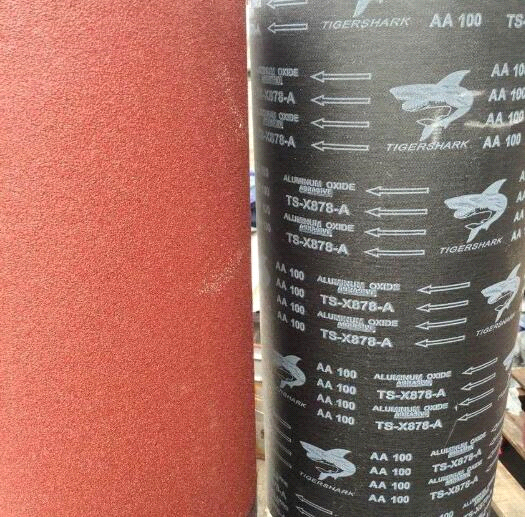

虎鲨牌氧化铝砂带是由X型布,密植砂为基体,高档氧化铝磨料,全树脂粘结剂的一种优质砂带,长久以来深受客户青睐,其表现为

1:砂带的磨粒比砂轮磨粒具有更强的切削能力,所以其磨削效率非常高。砂带磨削效率高表现在它的切除率、磨削比(切除工件重量与与磨料磨损重量之比)和机床功率利用率三个方面都很高。到2012年,已知的砂带磨削对钢材的切除率已达到700mm3/mm·s,甚至超过了车削或铣削等。砂带的磨削比大大超过了砂轮,高达300:1,甚至400:1,而砂轮才30:1。砂带磨床的功率利用率,远在砂带磨削发展初期就已达到80%

2.冷态磨削

砂带磨削工件表面质量高。这除了因其具有磨削、研磨和抛光的多重作用外,还因为:相对砂轮磨削而言,砂带磨削有"冷态磨削"之称,即磨削温度低,工件表面不易出现烧伤等现象。

3.磨削震动

砂带磨削系统震动小且稳定性好。由于砂带本身质量轻,其磨削工艺结构系统的平衡状态易于控制,所有的回转部件(如接触轮、驱动轮、张紧轮等)磨损极小,不会出现象砂轮那样的动不平衡因素。

此外,砂带的弹性磨削效应能够大大减轻或吸收磨削时产生的震动和冲击。磨削速度稳定,砂带驱动轮不会象砂轮一样越磨直径越小速度越慢。

4.粗糙度

砂带磨削工件表面质量高主要表现在表面粗糙度值小,残余应力状态好,以及表面无微观裂纹或金相组织变化等现象。

规格:915*100mm;610*100m;533*75mm;520*20mm;330*10mm

粒度:36#40#60#80#100#120#150#180#240#320#400#600#

Tiger Shark Alumina Belt is a kind of high quality abrasive belt made of X-shaped cloth, densely planted sand as matrix, high-grade alumina abrasives and all-resin binder. It has been favored by customers for a long time. Its performance is as follows:

1: The abrasive grain of abrasive belt has stronger cutting ability than the abrasive grain of wheel, so its grinding efficiency is very high. The efficiency of abrasive belt grinding is high in three aspects: the cutting rate, the grinding ratio (the ratio of the weight of the workpiece to the weight of abrasive wear) and the power utilization ratio of the machine tool. By 2012, the known removal rate of steel by abrasive belt grinding has reached 700 mm3/mm.s, even exceeding turning or milling. The grinding ratio of abrasive belt is much higher than that of grinding wheel, up to 300:1 or even 400:1, while that of grinding wheel is only 30:1. The power utilization ratio of abrasive belt grinder has reached 80% far from the early development stage of abrasive belt grinding.

2. Cold grinding

Abrasive belt grinding workpiece surface quality is high. This is not only because of its multiple functions of grinding, grinding and polishing, but also because: relative to wheel grinding, belt grinding is known as "cold grinding", that is, low grinding temperature, workpiece surface is not easy to appear burns and other phenomena.

3. Grinding vibration

The abrasive belt grinding system has small vibration and good stability. Because of the light weight of the belt itself, the balance state of the grinding process structure system is easy to control, and all rotating parts (such as contact wheel, driving wheel, tension wheel, etc.) wear very little, and there will be no dynamic unbalance factors like grinding wheel.

In addition, the elastic grinding effect of abrasive belt can greatly reduce or absorb the vibration and impact produced during grinding. The grinding speed is stable, and the smaller the grinding diameter, the slower the grinding speed is.

4. roughness

The high surface quality of abrasive belt grinding workpiece is mainly manifested in the small surface roughness, good residual stress state, and no micro-cracks or changes in metallographic structure on the surface.

Specifications: 915*100mm; 610*100m; 533*75mm; 520*20mm; 330*10mm

Granularity: 36 # 40 # 60 # 80 # 100 # 120 # 150 # 180 # 240 # 400 # 600 #.